Description

What is it?

Cast acrylic sheets (PMMA) offer higher quality than extruded acrylic. Acrylic (also known by trade names like Perspex or Plexiglass) is a rigid plastic with a very high degree of transparency. Its density is less than half that of glass, but its impact resistance is much greater.

It can transmit up to 92% of visible light and is perfect for outdoor applications: all plates contain a UV absorber to ensure that colors last over time.

This plastic tends to scratch easily. It can be cleaned with a mild solution of lukewarm water and dish soap. It must never be cleaned with other non-specific detergents or dry cloths (except microfiber)!

Notes for the design

Laser cutting on 3mm acrylic tends to "burn" 0.2mm across the cutting line.

The details should not be smaller than 1mm, because they would become too fragile.

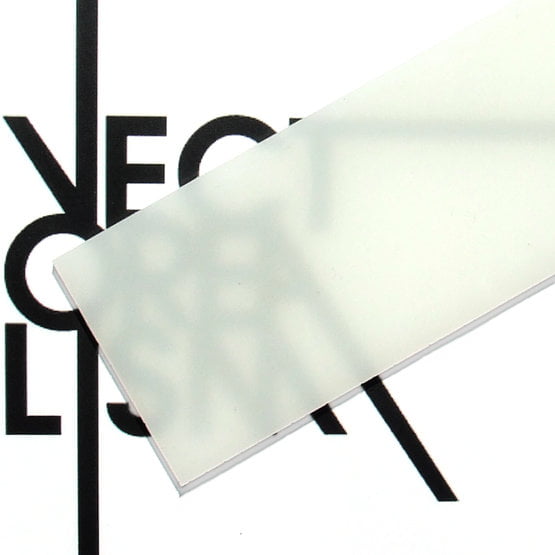

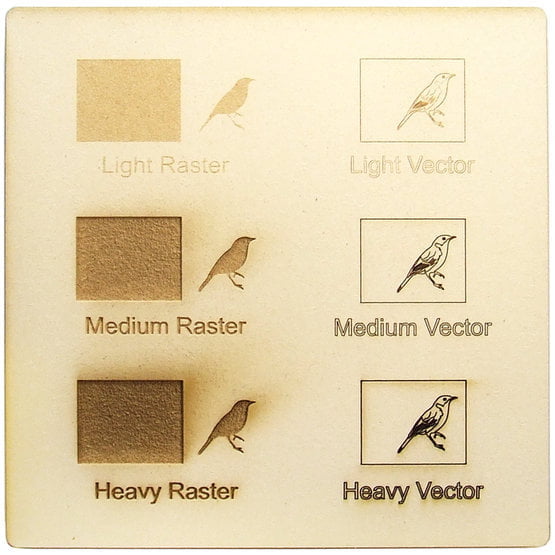

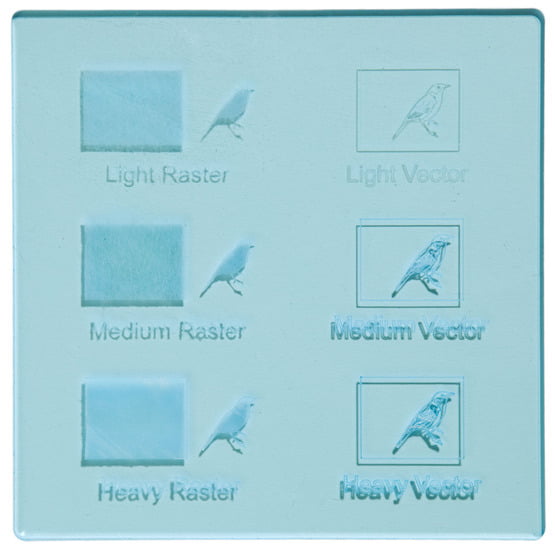

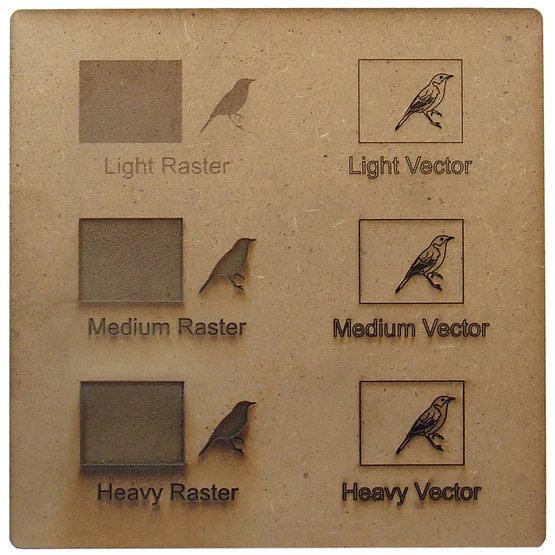

Files containing light, vector or raster engravings will be processed without protective film on the upper surface of the material.

The rounded corners can reduce the risk of breakage compared to right angles.

The acrylic sheets have a tolerance of +/- 10% compared to the nominal thickness.

It is used for ...

furnishing accessories, jewelery, homes for electronics, models.

Ecological information

Acrylic is a recyclable material, but in Italy it is not yet possible to differentiate it.

Gluing, joints and fixings

It can be glued with specific adhesives for plexiglass, special solvents, chloroform. Non-specific adhesives can deform or stain the surface.

It is possible to design three-dimensional objects with removable or permanent joints. It is also possible to use screws and bolts to join different parts in acrylic.

It can also be glued onto other materials.

Dettagli tecnici

Depth medium raster engraving: 0.25 mm

Depth deep raster engraving: 0.60 mm

kerf: 0.2 mm

measured on the sample (59.8 mm measured after the drawing cut with 60 mm side)

All values are purely indicative and are subject to variations based on the sheet of material and the position at the time of processing.