Material details

The laser cutting process on metals is different than the other materials in the catalog.

Before proceeding with laser cutting on metal, be sure to carefully read the description of the material listed below.

Spessori disponibili: 1.5 mm, 2.0 mm, 3.0 mm, 5.0 mm

Description

The laser cutting process on metals is different than the other materials in the catalog. Before proceeding with laser cutting on metal, be sure to read these important indications:

- it is not possible to share cutting lines

- you will only receive the cut pieces, not the rest of the plate. It is not possible to receive both positive and negative. If you intend to make a stencil you need to draw the border around your design and you will only receive the template.

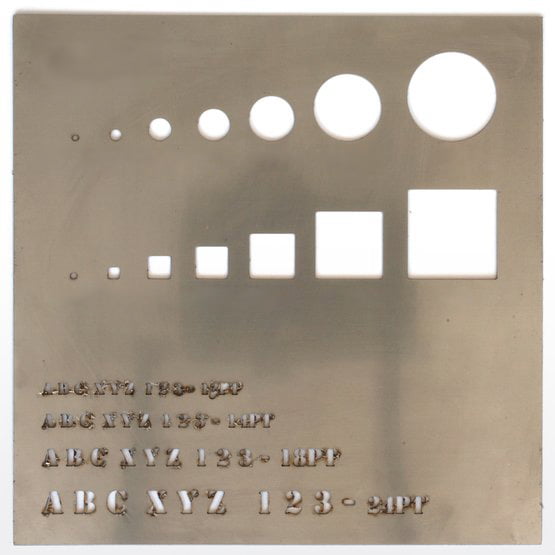

- the objects must have an area of at least 10x10mm (the grid on which the slab rests is very large, the smaller pieces of this size will fall and it will not be possible to recover them)

- the elements on the template must be 6mm apart from each other

- it's better avoid details with a width of less than 1mmbecause they could be burned away and not be on the final object

- it is also necessary to create "carrier" details of width equal to or greater than the thickness of the material. In any case never less than 1mm. For example, if I choose to use a 3mm plate, the minimum thickness within my design should be 3mm. If I choose to use a plate with a thickness of 0.5mm, the minimum thickness within the design must be 1mm.

- draw using only closed paths

- before cutting an object, the laser can drill on the outside of the cutting line

- in the smaller elements, the corners may be rounded

- the back of the material will be slightly satin for the process of cleaning and removing the burns after cutting

- can make incisions using the average vector engraving (green colour). It is not possible to make incisions of different intensities or raster engravings.

- If in doubt, write a note before adding your drawing to the cart!

[/wvc_list]

Technical details

Il ferro nero ha una patina di calamina che conferisce una colorazione bluastra molto scura, tendente al nero.

Ferro is the name given in the language common to iron alloys. Our material is therefore precisely called carbon steel. The term carbon steel indicates an iron-carbon alloy containing no different elements except as impurities.

The iron works easily and can be welded without problems. It has excellent tensile and compressive strength. It is subject to corrosion (rust). After cutting, the objects are cleaned mechanically to eliminate stains and smudges due to laser cutting. Nevertheless, there may be some "burrs" in hard-to-reach areas, which are not larger than 1mm, due to a slight melting of the material.

Parts near the cut can change color. The whole can be removed and cleaned with specific abrasive paste (also available in supermarkets), solvents or sandpaper. The iron is recyclable. It can be worked with mechanical tools and fixed or joined with small metal parts. It can be welded. For gluing onto other materials it is possible to use specific glues.